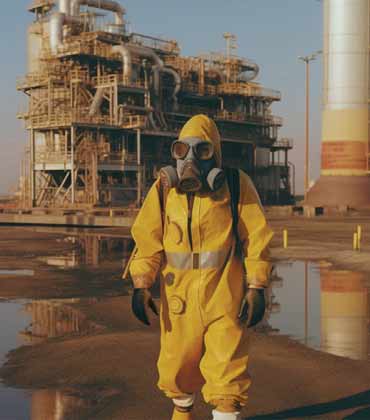

Every barrel of drilling waste that leaves a rig begins a chain of responsibility that can last for years. Once hazardous materials are loaded and hauled to a disposal site, operators join a long list of parties tied to whatever happens next. The familiar practice is rarely questioned, even though the transport itself poses risks to crews, landowners and the environment. Mike Gibson, a chemist and industrial management graduate from Purdue University, has never been one to follow convention. Working in refineries and petrochemical plants, including his time at Nalco Chemical Company, Nalco/Exxon Energy Chemicals and GE, Gibson observed the established waste practices used to handle hydrocarbons. Slop oils, tank bottoms and oily sludges were separated in centrifuges or handled at the Waste Water Treatment plant. The approach worked well enough for disposal, but not for in-situ remediation. He began studying how water chemistry could break down hydrocarbons in a way that allowed the soil’s natural remediation process to take over. That exploration became the foundation for him to start his own company, Evergreen Chemical Solutions, and create an innovative solution, EverGreen 12. EverGreen 12 is a proprietary blend of Ethoxylated Octylphenolic Surfactants, nonionic water-based liquid. A surfactant formulation that is fully miscible with water. When mixed and agitated, it breaks down hydrocarbons such as gas, diesel, crude oil and grease into microscopic droplets to form a stable microemulsion. Without added microbes or enzymes, the dispersed hydrocarbons cannot reform and become available for native soil microbes to absorb, initiating a natural biodegradation pathway. Through this process, the hydrocarbons are converted into water and carbon dioxide, leaving treated soil free of hydrocarbon residues.

Lithium-Ion Cathode Materials

Manufacturers in the electric vehicle (EV) industry are on a relentless quest for the ultimate battery. They’re seeking high-performance energy storage solutions that offer superior energy density, lightning-fast charging, low costs, unmatched durability, and top-tier safety—demands that extend beyond just power. However, achieving this balance requires significant advances in battery chemistry, engineering, and thermal management systems. Amidst these needs, the industry has been seeking a breakthrough solution to balance safety, cost, and performance— an opportunity Stratus Materials has seized. The company has raised the bar for batteries by developing and producing cobalt-free lithium manganese rich (LMR) cathode active materials (CAMs) that enhance energy storage performance while ensuring safety and thermal stability for optimal battery performance in EVs. Stratus’s brand name for its proprietary CAMs is LXMOTM. Stabilizing Cathode Technology Where many companies in the battery materials space focus on innovations on the anode side of the battery, Stratus Materials’ innovation stands apart because it is on the cathode side. It is one of the only companies to have proven that cobalt-free, LMR materials can be optimized and truly stabilized (as opposed to using coatings or advanced electrolytes, which offer only limited improvements).

Biomass Gasification Company

For one of Argentina’s largest olive oil producers, waste management had long been a costly and environmentally damaging challenge. Massive amounts of organic residues— wood from tree pruning and olive pits—were either burned or discarded in ways that harmed the fragile desert ecosystem. That was until Eduardo M. Lora, founder & CEO of LatAm BioEnergy™, stepped in. After assessing the site, he told them, “You have an oil field in your backyard, and you don’t even realize it.” His intervention brought about a visible and impactful change for the Olive producer. LatAm BioEnergy™, a cleantech company, renowned for designing, building, selling, and financing tailored biomass gasification solutions This success story reflects LatAm BioEnergy™’s broader mission: helping agro-industries become more profitable, resilient, and sustainable through cutting-edge clean technology. The Modular BioRefinery: A Smarter Way to Power Agro-Industries At the core of LatAm BioEnergy™’s innovation is the Modular BioRefinery, a 24/7 system that converts agricultural waste— including coconut shells, rice husks, wood chips, and olive and co-generation systems that use AI, helped them create a circular economy. The company converted all their wood chips and olive pits into gas—a valuable resource—rather than burning the biomass or throwing it away. This gas was then used to generate electricity, enabling the olive oil producer to power operations using their own waste, which immediately reduced their energy costs. This success story reflects LatAm BioEnergy™’s broader mission: helping agro-industries become more profitable, resilient, and sustainable through cutting-edge clean technology. The Modular BioRefinery: A Smarter Way to Power Agro-Industries At the core of LatAm BioEnergy™’s innovation is the Modular BioRefinery, a 24/7 system that converts agricultural waste— including coconut shells, rice husks, wood chips, and olive press residues—into clean energy sources such as: Biomass gas – A sustainable alternative to fossil fuels Electricity & heat – For on-site industrial use BioChar – A byproduct that enhances soil fertility and sequesters carbon This regenerative approach not only eliminates waste but also improves agricultural productivity, restoring ecosystems and reducing dependency on fossil fuels. “Our vision is to foster a future where agro-industries are profitable, sustainable, competitive, and less dependent on fossil fuels and its price fluctuation. Our approach to achieving this is to focus on making significant impacts across four key areas: economic, social, environmental, and technological,” says Lora. Another success story comes from the Dominican Republic, where LatAm BioEnergy™’s Modular BioRefinery was deployed at an animal feed production facility, transforming coconut shells and wood chips into electricity, steam, and biochar. This innovative solution not only reduces energy costs and reliance on fossil fuels but also enhances production efficiency and environmental sustainability, setting a new benchmark for clean energy adoption in agro industrial operations. Making a True Impact on the Industry Economically, the company helps clients achieve cost savings and improve efficiency. Socially, it contributes by creating green jobs and promoting sustainable development. Environmentally, LatAm BioEnergy™ drives industry-wide decarbonization. Technologically, it transforms agro industrial operations with clean, renewable energy solutions.

CXO INSIGHTS

The Key To Reducing Fuel Consumption And Reduced Environmental Footprint

Frode Jensen, President Rig Technologies, National Oilwell Varco [NYSE: NOV]

Renewable Energy - A More Adaptive And Responsive Choice

Warren Boutin, Vice President, Customer Grid Electrification Solutions and Experience, Eversource Energy [NYSE: ES]

Innovation in Renewable Energy Asset Management

Robert Gomez, Head of Onshore Asset Management, Ørsted [CPH: ORSTED]

Building Equitable Pathways in Western Energy

Pamela Sporborg, Director, Transmission & Markets, Portland General Electric [NYSE: PGE]

Creative Procurement Solutions

Ken Jones, Senior Director of Business Services, EPB [NYSE: EPB]

IN FOCUS

Chemical Remediation as ESG Risk Management in Oil and Gas

Chemical remediation is now vital for oil and gas firms to rapidly manage contamination, meet strict ESG regulations, reduce financial risks, and demonstrate responsible governance through targeted, low-impact solutions.

Chemical Remediation as a Strategic Enabler of the Energy Transition

Chemical remediation is now vital in supporting the energy transition, enabling land reuse, sustainable mineral extraction, and greener cleanup practices for a cleaner, low-carbon industrial future.

EDITORIAL

Rethinking Chemical Remediation in Energy

The oil and gas industry continues to face mounting pressure to manage drilling waste responsibly while reducing long-term environmental and operational risk. This edition of Energy Tech Review examines how practical chemistry, applied at the point of waste generation, is reshaping remediation standards and liability outcomes across the sector.

Our cover story recognises Evergreen Chemical Solutions as the Top Oil and Gas Chemical Remediation Solution 2026. Evergreen has redefined remediation by treating hydrocarbons in situ rather than exporting risk offsite. Its proprietary EverGreen 12 formulation uses water-based, nonionic surfactant chemistry to break hydrocarbons into stable microemulsions, enabling natural biodegradation without caustic reactions, added microbes or heavy equipment.

By converting hazardous drilling waste into non-hazardous material within weeks, Evergreen has delivered measurable reductions in transport exposure, safety risk, and disposal costs, while consistently driving oil-on-cuttings levels to around 1 percent or less. The result is a scalable, repeatable remediation model that closes the loop at the wellsite and materially shortens environmental closure timelines.

CXO perspectives add further depth. Jeremy Angelle, VP of Well Construction at Expro [NYSE: XPRO], outlines a structured framework for quantifying value in drilling automation, anchored in safety, well integrity, efficiency and reliability. His analysis demonstrates how disciplined evaluation converts technology adoption from risk into measurable return.

Enoch Charles, Information Technology – Smart Grid Transport Manager at CenterPoint Energy [NYSE: CNP], examines how intelligent, resilient networks strengthen future energy systems, emphasising reliability, security and human-centric design as non-negotiable foundations.

Together, these contributions highlight that leadership in today’s energy sector is defined by solutions that are technically sound, operationally proven, and accountable throughout their lifecycle. We invite readers to explore this issue in detail and engage with the ideas shaping the next phase of responsible energy operations.