CLOSE

Specials

I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Be first to read the latest tech news, Industry Leader's Insights, and CIO interviews of medium and large enterprises exclusively from Energy Tech Review

Thank you for Subscribing

Advanced Processing Tools Powering the APAC Battery Revolution

The APAC region leads global battery production, fueled by EV demand and advanced processing techniques, enhancing efficiency and sustainability throughout the lithium-ion value chain.

By

Energy Tech Review | Tuesday, November 11, 2025

Stay ahead of the industry with exclusive feature stories on the top companies, expert insights and the latest news delivered straight to your inbox. Subscribe today.

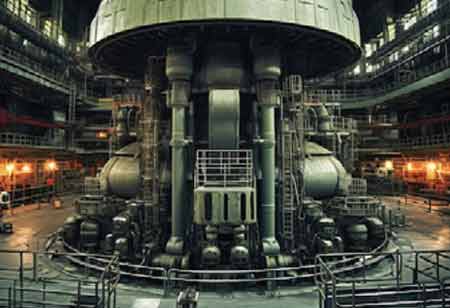

Fremont, CA: The Asia-Pacific (APAC) region stands as the undisputed global epicenter of the battery revolution, dominating the manufacturing of lithium-ion battery components and cells. This monumental ascent, fueled by massive demand for Electric Vehicles (EVs) and grid-scale Energy Storage Systems (ESS), is underpinned by the continuous innovation and rapid adoption of advanced processing tools throughout the value chain—a critical journey from raw ore to finished electrode.

The Midstream Advantage: Refining and Material Synthesis

APAC’s dominance in the global battery value chain stems from its strength in the midstream segment. On this critical stage, raw materials are refined and transformed into high-purity battery components. This process demands advanced expertise in chemical engineering and materials science to ensure the performance, safety, and longevity of lithium-ion batteries. In the high-purity chemical refining stage, ores containing lithium, nickel, cobalt, and manganese are converted into chemical precursors such as lithium hydroxide (LiOH) and nickel sulfate (NiSO₄). China leads this capability, while countries like Australia are rapidly expanding their refining infrastructure, leveraging their mineral wealth. Innovations such as Direct Lithium Extraction (DLE) are further enhancing efficiency by enabling faster, more sustainable conversion of brines into battery-grade compounds. The subsequent stage—active material synthesis—involves converting these precursors into Cathode Active Materials (CAMs) such as NMC (Nickel Manganese Cobalt), LFP (Lithium Iron Phosphate), and NCA (Nickel Cobalt Aluminum), as well as Anode Active Materials (AAMs) like graphite and silicon-based composites. This process relies on advanced reactors and controlled precipitation systems to engineer particle size, morphology, and crystal structure with precision. Such meticulous control is vital, as it directly determines a battery’s energy density, charge rate, and cycle life, solidifying APAC’s position as the world’s midstream powerhouse.

Next-Generation Electrode Manufacturing: The Precision Imperative

The electrode lies at the heart of the battery cell, and APAC manufacturers are at the forefront of transforming electrode fabrication through precision engineering and digital innovation. Traditional methods of slurry mixing with solvents such as N-Methyl-2-pyrrolidone (NMP) are being replaced by advanced, environmentally friendly techniques. Modern high-shear mixers and vacuum drying systems ensure uniform dispersion of active materials, binders, and conductive additives—an essential factor in achieving consistent electrochemical performance. Similarly, high-speed slot-die coating technologies enable the application of ultra-thin, even slurry layers onto copper (for anodes) and aluminum (for cathodes), enhancing both efficiency and product quality. A significant leap forward in this domain is the rise of dry electrode processing, a solvent-free technique increasingly adopted across APAC. By eliminating volatile solvents and energy-intensive drying, this approach significantly reduces carbon emissions and production costs while improving electrode density and mechanical integrity through advanced dry-mixing, binder fibrillation, and calendaring.

Complementing these innovations, AI-driven process control systems are now being deployed to monitor key parameters such as slurry viscosity, coating thickness, and calendaring pressure in real time. This integration of advanced analytics ensures higher yields, reduced waste, and superior consistency—key advantages as APAC moves toward giga-scale production. The region’s growing investment in advanced hydrometallurgical and pyrometallurgical recycling technologies—particularly in China and South Korea—closes the loop in the battery value chain. By recovering high-purity materials like lithium, nickel, and cobalt from spent batteries, APAC’s midstream ecosystem reinforces its sustainability goals and secures long-term supply resilience.

The integration of the advanced processing tools—from innovative direct extraction at the ore stage to solvent-free electrode fabrication and high-efficiency material recovery—is the engine driving the APAC battery revolution, securing its competitive edge and accelerating the global shift towards electrified transport and sustainable energy grids.

Copyright © 2025 Energy Tech Review. All rights reserved