CLOSE

Specials

I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Be first to read the latest tech news, Industry Leader's Insights, and CIO interviews of medium and large enterprises exclusively from Energy Tech Review

Thank you for Subscribing

Clean Combustion Breakthroughs: The Role of Digital Twins

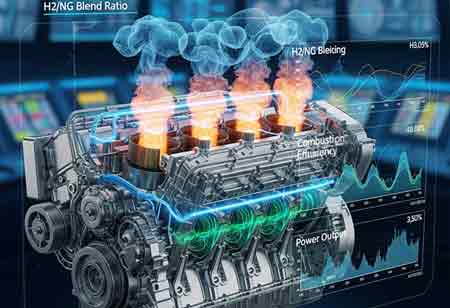

Decarbonization drives the adoption of hydrogen-blended natural gas, utilizing digital twin technology to optimize engine performance, enhance safety, and reduce carbon emissions efficiently.

By

Energy Tech Review | Monday, December 29, 2025

Stay ahead of the industry with exclusive feature stories on the top companies, expert insights and the latest news delivered straight to your inbox. Subscribe today.

Fremont, CA: The drive for cleaner fuels and improved energy systems has accelerated due to the global need for decarbonization. Because of its zero-carbon combustion characteristics, hydrogen is an attractive option. However, the full transition to a hydrogen-only economy is a long-term goal. Integrating hydrogen with natural gas, or hydrogen-blended natural gas, is a quicker and more practical solution. This approach makes use of current infrastructure and traditional engine technologies to enable a gradual decrease in carbon emissions.

The Digital Twin Approach: A Virtual Engine for Real-World Solutions

At the heart of the optimisation process lies the digital twin—a sophisticated virtual replica of a physical system, in this case, a hydrogen–natural gas engine. Unlike a static blueprint, the digital twin is a dynamic, data-driven simulation that mirrors the engine’s real-time performance, thermodynamics, and combustion dynamics with high precision. It integrates multiple advanced modelling approaches, including Computational Fluid Dynamics (CFD) models, which simulate the intricate flow of gases, fuel injection, and mixing within the combustion chamber to analyse ignition and combustion behaviour; chemical kinetics models, which predict the chemical reactions during combustion and the formation of emissions such as NOₓ; and thermodynamic and mechanical models, which assess heat transfer, pressure fluctuations, and mechanical stresses to anticipate potential issues and enhance durability. The digital twin allows engineers to explore thousands of fuel blend ratios, operating conditions, and design modifications without the associated costs and delays of physical prototypes.

Accelerating Adoption and Ensuring Safety

The deployment of integrated modeling and digitalization tools significantly diminishes the time and expenditure associated with research and development. While conventional physical testing can span several years, a digital twin facilitates rapid iteration and espouses a "fail fast" methodology, enabling engineers to identify and rectify design deficiencies within the virtual environment promptly.

Likewise, the digital twin assumes a pivotal function in ensuring safety. Through the simulation of potential combustion irregularities, such as flashbacks and knocking, engineers are empowered to devise resilient control systems and engine architectures that ameliorate these risks before the construction of a physical engine. This instills confidence in both manufacturers and end-users, thereby further expediting the widespread adoption of this environmentally sound technology.

The digital twin transcends mere simulation, functioning as a strategic asset in the clean energy transition. By establishing a virtual laboratory for hydrogen–natural gas engines, their complete potential can be realized, thereby facilitating a more sustainable future across both industrial and transport sectors.

Copyright © 2025 Energy Tech Review. All rights reserved