CLOSE

Specials

I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Be first to read the latest tech news, Industry Leader's Insights, and CIO interviews of medium and large enterprises exclusively from Energy Tech Review

Thank you for Subscribing

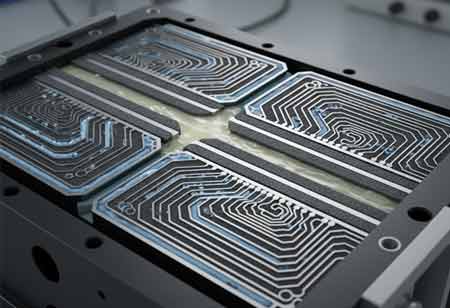

Bipolar Plates as the Heart of Hydrogen Fuel Cells

The bipolar flow plate (BPP) is crucial to hydrogen fuel cell performance, durability, and cost, significantly impacting Europe's decarbonization and energy independence goals.

By

Energy Tech Review | Friday, November 21, 2025

Stay ahead of the industry with exclusive feature stories on the top companies, expert insights and the latest news delivered straight to your inbox. Subscribe today.

Fremont, CA: Hydrogen fuel cells are a cornerstone of the European Union's strategy for decarbonization and achieving energy independence. Among the components that determine a fuel cell's success, the bipolar flow plate (BPP) is arguably the most critical for both performance and long-term durability. Often representing up to 80 per cent of the fuel cell stack's total weight and cost, the BPP's design and material are central to the commercial viability and widespread adoption of this technology across Europe's transport and stationary power sectors.

Critical Impact on Fuel Cell Performance

The design of the Bipolar Plate (BPP) plays a decisive role in determining a fuel cell’s power output, voltage stability, and overall energy efficiency. A key factor is the flow-field geometry, where optimising power density requires balancing pressure drop and reactant distribution. Serpentine, parallel, and pin-type flow patterns each offer advantages and limitations: complex geometries, such as serpentine channels, promote uniform reactant distribution across the active area, enhancing electrochemical reaction rates and maximising power generation. However, this uniformity comes at the cost of a higher pressure drop, which increases parasitic power consumption and reduces system-level efficiency. Effective mass transport is equally critical. The flow channels must continuously deliver fresh reactants to the Gas Diffusion Layer (GDL) while efficiently removing product water. Inadequate mass transport leads to concentration overpotentials that substantially reduce cell voltage and impair performance.

Electrical contact resistance also directly affects power output. To maintain high voltage, the interface between the BPP and adjacent GDLs must exhibit minimal resistance. This requires BPP materials with high bulk electrical conductivity and exceptionally low interfacial contact resistance (ICR)—any increase in ICR results in reduced stack efficiency and increased overall energy losses.

Importance of Durability and Lifetime

Europe’s push for large-scale fuel cell deployment—particularly in heavy-duty mobility and stationary backup power—demands operational lifetimes that exceed 20,000 hours. The choice of BPP material is central to achieving this durability. Fuel cells operate in an aggressive environment characterised by humidity, acidity, and electrochemical activity, making corrosion resistance a top priority. While graphite-based plates generally offer excellent chemical inertness, metallic BPPs are prone to forming insulating oxide layers that significantly increase interfacial contact resistance over time. This corrosion challenge remains the most significant barrier to long-term performance in metallic plates. Materials must prevent the leaching of ions such as iron or chromium into the membrane, as these contaminants accelerate catalyst degradation and membrane ageing.

Mechanical stability is another critical requirement. The BPP provides structural support to the membrane and GDLs while ensuring robust sealing. Throughout the stack’s operational life, frequent thermal cycling causes expansion and contraction stresses. The plate must maintain mechanical integrity, preserve sealing surfaces, and prevent hydrogen-air crossover or coolant leakage—failures that can rapidly compromise stack safety and functionality.

In Europe, ongoing research and industry trends centre on two dominant BPP categories: graphite/composite plates and metallic plates such as stainless steel or titanium. Graphite plates offer excellent corrosion resistance and lower weight but require thicker profiles, resulting in lower power density and higher tooling costs for compression moulding. Metallic plates, by contrast, deliver superior conductivity and can be manufactured at skinny dimensions—down to 0.1 mm—enabling compact, high-power-density stacks. However, they require advanced, ultra-thin protective coatings to mitigate corrosion. High-speed stamping and hydroforming techniques make metallic BPPs particularly suitable for mass-market production, aligning with Europe’s industrialisation goals for fuel cell technologies.

European manufacturers are increasingly focused on stamped metallic BPPs coated with materials like PVD-applied carbon or noble metal alloys. This approach offers the best combination of high power density (due to thinness), low cost (due to high-speed manufacturing), and acceptable durability, which is key to making fuel cell electric vehicles (FCEVs) cost-competitive with battery electric vehicles (BEVs) and internal combustion engine (ICE) vehicles.

The bipolar flow plate is far more than just a structural component. Its design and material directly encode the performance, cost, and lifespan of a hydrogen fuel cell, making it a pivotal area of research and innovation for achieving Europe's clean energy objectives.

Copyright © 2025 Energy Tech Review. All rights reserved